NEWS

2017 AWARD OF CHAMBER OF COMMERCE OF THE REPUBLIC OF SERBIA

Marko Čadež President of the Chamber of commerce of the Republic of Serbia, Miloš Ljušić General Manager of Umka Cardbord Mill , Miroslav Tlačinac President of the Award committee. Umka Cardboard Mill, has received an award in the company category for 2017 in the...

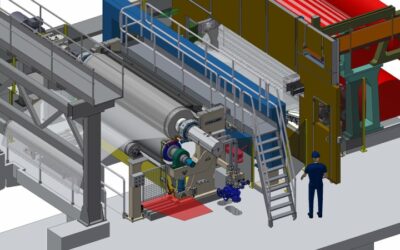

RECONSTRUCTION OF THE MACHINE – 2017.

Umka Cardboard mill has successfully completed the first part of the investment cycle in August this year, by installing the first phase of the deinking plant and the hard hot nip calendar. The machine was successfully restarted and is currently in the tuning phase....

INTEGRATION OF THE PALLET PRODUCTION FACILITY

In September 2017 Umka Cardboard mill has integrated the pallet production facility. By joining the operations in this way, the mill is achieving better control and securing the supply of pallets, especially taking into consideration huge number of different pallet...

NEW INVESTMENT CYCLE

In accordance with the policy of continuing investments and development, quality improvements and production capacity increase, Umka Cardboard Mill is starting a new investment cycle between 2017 and 2019 with a budget of cca 15 milion EUR. This investment cycle will...

AUTOMATED PACKAGING LINE

As a part of the overall efforts to increase production capacity, the mill has installed and automated packaging line for packaging of finished products. The main goal of the installation is to improve the packaging and keep up with the latest trends of packaging of...

REPLACEMENT OF THE DRYING HOOD

Extended annual maintenance of the cardboard machine has been completed at the end of July 2013. A complete maintenance and checkup of the machine has been performed with special attention to maintenance of the stock preparation line, replacement of vacuum pumps...

NEW PRODUCTS

Products in the production portfolio of Umka Cardboard mill have their application in the packaging of products from various tips of industries. Inspired by increasing requests from customers Umka Cardboard mill has in cooperation with a partner company from Serbia...

INCREASE OF WAREHOUSE CAPACITY

As a part of the plans to increase production and sales in the next couple of years and as a part of initial phase to create the necessary preconditions , at the end of 2013 we finalized the project of extending the warehouse capacity for finished products. The...

RECONSTRUCTION OF THE CARDBOARD MACHINE

At the end of April , as a part of the investment process planned for year 2013 , a reconstruction of the cardboard machine has been performed, which should together with other planned investments enable the reach of 125 000t annual production capacity. During the...

NEW CARDBOARD CUTTER

Production capacity increase opened a bottle neck in the sheeting and finishing section. With a goal to eliminate this bottle neck and to increase of flexibility in the sheeting section through faster and more efficient response to customers requests , the additional...